|

Roaming the internet I found:

In 1976 the Alberta Wheat Pool revealed its intent to build a new elevator at the siding in Leduc. It wanted an elevator that would have a large enough capacity to replace all their aging elevators on the row, allowing for easier and more efficient grain handling. A single composite elevator built to the standard design stood normally over 90 feet tall. This was considered a navigational hazard for airplanes approaching the airport

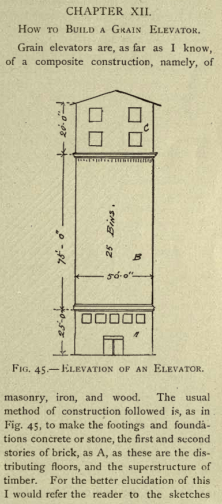

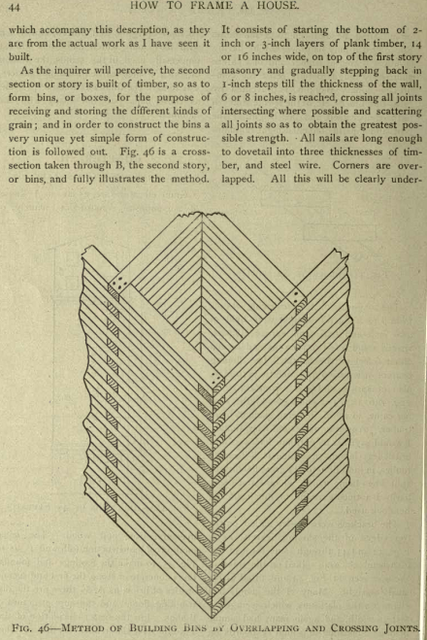

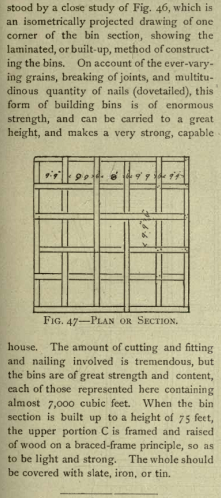

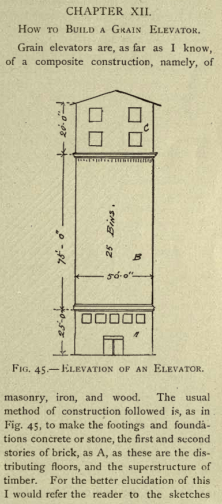

All elevators were basically built the same way. First a hole was excavated, cement foundation pads were poured and the steel pan set flush in the pit. The crew began construction of the sturdy cribbed walls, built to withstand the weight of the grain. The cribbing timbers were laid flat and spiked together. The cribbing of the exterior walls continued in rounds, in step with the cribbing of the inside bins, so that the elevator rose at an even height. As the cribbing progressed the crew installed the leg to elevate the grain, the distribution spout or gerber, the hopper and scales on the work floor, and the loading spout to the track below. The cupola on top was put together with pre-cut wood studs and shiplap or plywood walls. Finally the driveway was added, and the whole structure was clad with wood siding.

At Leduc, as Pearson later explained, changes had to be made to the standard plan. Instead of the standard 67 foot walls, the walls and bins were cribbed up only 59 feet, and the cribbing strength was reduced proportionately to the overall height of the building. The standard rounds of 2 by 6 cribbing were reduced by 5 feet and the higher 2 by 4 cribbing by 3 feet. To partially compensate for the lost volume, the design incorporated an annex 10 feet longer than was standard, giving the structure a footprint of 38 feet by 100 feet.

The flight path-friendly elevator, with a capacity of 121, 000 bushels, was more expensive than a standard elevator. It cost $592,752 to build and opened in December 1978—the official ribbon cutting deferred until April 1979. It proudly served the farmers of Leduc until July 2000. When its days were clearly numbered and it, too, was faced with demolition the newly formed Alberta Legacy Development Society sprang into action to ensure its survival. Designated as a Provincial Historic Resource in 2003 and with fresh coat of paint in September 2007, it flaunts the once familiar and omnipresent Alberta Wheat Pool crest and logo.

Jack Winegar www.VCLCo.com On April 16, 2019 at 11:44 AM "Louis Zadnichek via Groups.Io" <LZadnichek=aol.com@groups.io> wrote:

April 16, 2019

Jack - Thanks. That's makes for an extremely strong construction - Louis

Louis Zadnichek II Fairhope, AL

In a message dated 4/15/2019 7:22:27 PM Central Standard Time, mrsafe@comcast.net writes:

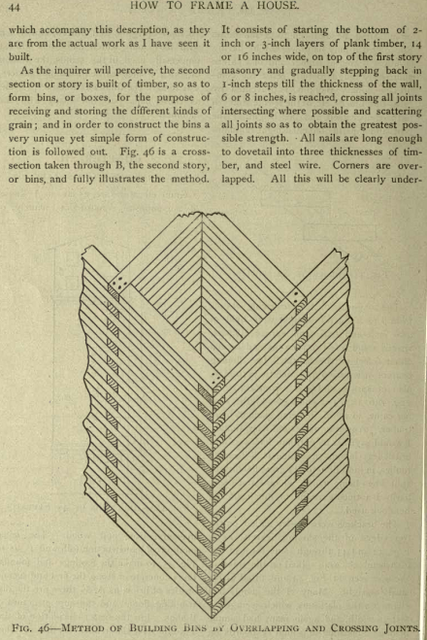

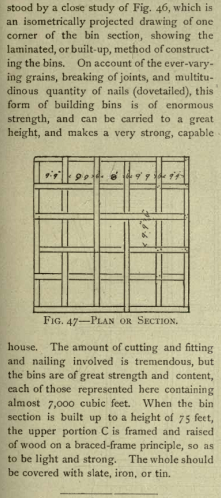

Hello Louis. Based on my limited knowledge of how wood Grain Elevators were built 100 years ago; Not all Grain Elevators were sided with wood or corrugated metal. The picture you sent appears to me to be built with dimensioned lumber laid on its side as shown on Fig. 46 below. Jack Winegar www.VCLCo.com

On April 15, 2019 at 12:40 PM "Louis Zadnichek via Groups.Io" <LZadnichek=aol.com@groups.io> wrote:

April 15, 2019

Doug - I'm attaching a post card view of the Q's Rulo, NE, yards dated 1912. Although the image is very faded, it gives a good look at the massive timber framed grain elevator complete with box cars for grain loading. Can you tell if the elevator is wood planked or sheathed in corrugated iron (or both)? This had to be one of the larger grain elevators in rural Nebraska for its era. This view will soon be posted in the BRHS Member's Section historical CB&Q Flickr photograph archive. Also, note the combination way car/combine at center. Best Regards - Louis

Louis Zadnichek II Fairhope, AL

In a message dated 4/15/2019 8:52:21 AM Central Standard Time, doug.harding@iowacentralrr.org writes:

Thanks for the history. I was not aware that corrugated iron had been around that long. From: CBQ@groups.io [mailto:CBQ@groups.io] On Behalf Of Gerry Michael via Groups.Io

Sent: Monday, April 15, 2019 8:04 AM

To: CBQ@groups.io

Subject: Re: [CBQ] CB&Q Grain Elevators, Grain Covered Hoppers, and Traffic I did a little poking around on the Internet and found few items that might be of interest.

A short article on the "History of Corrugated Iron" at https://www.world-archaeology.com/features/history-of-corrugated-iron/

A few excerpts from the article:

"The story starts with Henry Palmer of the London Dock Company who, in 1829, took out a patent for ‘indented or corrugated metallic sheets’. "

" By the end of 1849, over 80,000 gold diggers and their hangers-on had arrived in California’s Sacremento Valley. San Francisco was ‘a bawdy, bustling, bedlam of mudholes and shanties’. Prefabricated wooden huts and tents sprouted but corrugated iron buildings were cheaper, fireproof and much more comfortable, according to Peter Naylor who shipped 500 of them from New York. British manufacturers were not slow off the mark. Edward T Bellhouse of Manchester sent houses of up to 12 rooms, complete with wallpaper and carpets. As the Californian market declined, the Australian gold rush kicked in."

The article is based on a book entitled Corrugated Iron: Building on the Frontier by Adam Mornement and Simon Holloway.

Another article at http://www.buffaloah.com/h/elev/hist/3/ has a section on the motivation for using corrugated iron siding for grain elevators: fireproofing and the relative costs of both the building materials and associated fire insurance. The article also notes that timber prices began to rise in the 1890s, which would also effect the relative costs of wood vs. corrugated iron.

Gerry Michael

On 4/15/2019 1:48 AM, Denny Anspach wrote: Some question has been raised about how early industrial corrugated iron siding, i.e. “wrinkle tin" came into use. The gargantuan former Sacramento SP Boiler Shop was constructed new with corrugated iron siding in 1887. This landmark building with its old siding intact (connected by working transfer table to the 26 bay Erecting Shop) is now a connected part of the California State Railroad Museum (as will be soon the Erecting Shop as well).

_._,_._,_

Groups.io Links:

You receive all messages sent to this group.

View/Reply Online (#57103) |

Reply To Group

|

Mute This Topic

| New Topic

Your Subscription |

Contact Group Owner |

Unsubscribe

[archives@nauer.org]

_._,_._,_

|