Among the astounding number of inherent design and fabrication problems and issues to deal with, the major problems were, and have been 1) a wimpy folded-metal power truck frame that would distort with the added weight necessary to get the train from A to B; 2) A riveted thin plastic spur gear train all gears cracked; 3) an orphan-sized worm gear that slipped on the odd sized hat bushing on which it was pressed; and 4) a clunky three pole motor not up to the task.

I replaced the cracked gears with brass; I replaced the motor with a fat short Sagami, but was finally defeated both by frame distortion under weight; and the slipping un-replaceable worm gear. Even on the bench it never really worked well.

I then tried a very fine Bullant power truck from Australia, which was simply not up to the task.

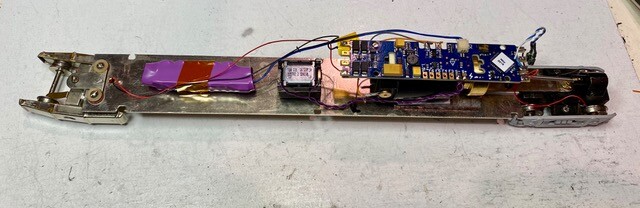

My last attempt has been to adapt an Overland/Ajin SW power truck with Overland drive (Kato motor). and this has been successful (photos below). The original NPP/KMT low relief side frames had to also be adapted because of the narrow constriction of the body skirting- quite a job. The Tsunami decoder is dialed into slow turning Baldwin diesel sounds (as close as possible to the Winton rattling). I added all wheel electrical pickup. No metalwork body or mount alterations were necessary. The train now crawls silently without any mechanical noise- none.

I have not yet tested it around the layout adding the train’s aftermarket third trailing car. The total weight on the power truck available for traction is 0.520 lbs.

Now, the next task is to create plausible full width diaphragms between the cars. The usual suspects do not work, i.e. Coach Yard, or American Limited. I crave suggestions from listers, especially success stories!

Denny

Denny S. Anspach, MD

Sacramento, CA 95864